Packaging Machine Repair Service: Stay Clear Of Hold-ups and Improve Efficiency

Recognizing the Key Parts and Repair Work Techniques for Product Packaging Machine Maintenance

Efficient upkeep of product packaging makers pivots on an extensive understanding of their key components, consisting of the frame, drive system, and sealing systems. Acknowledging usual upkeep problems, coupled with the application of preventative strategies and troubleshooting methods, can substantially improve machine dependability.

Trick Elements of Packaging Devices

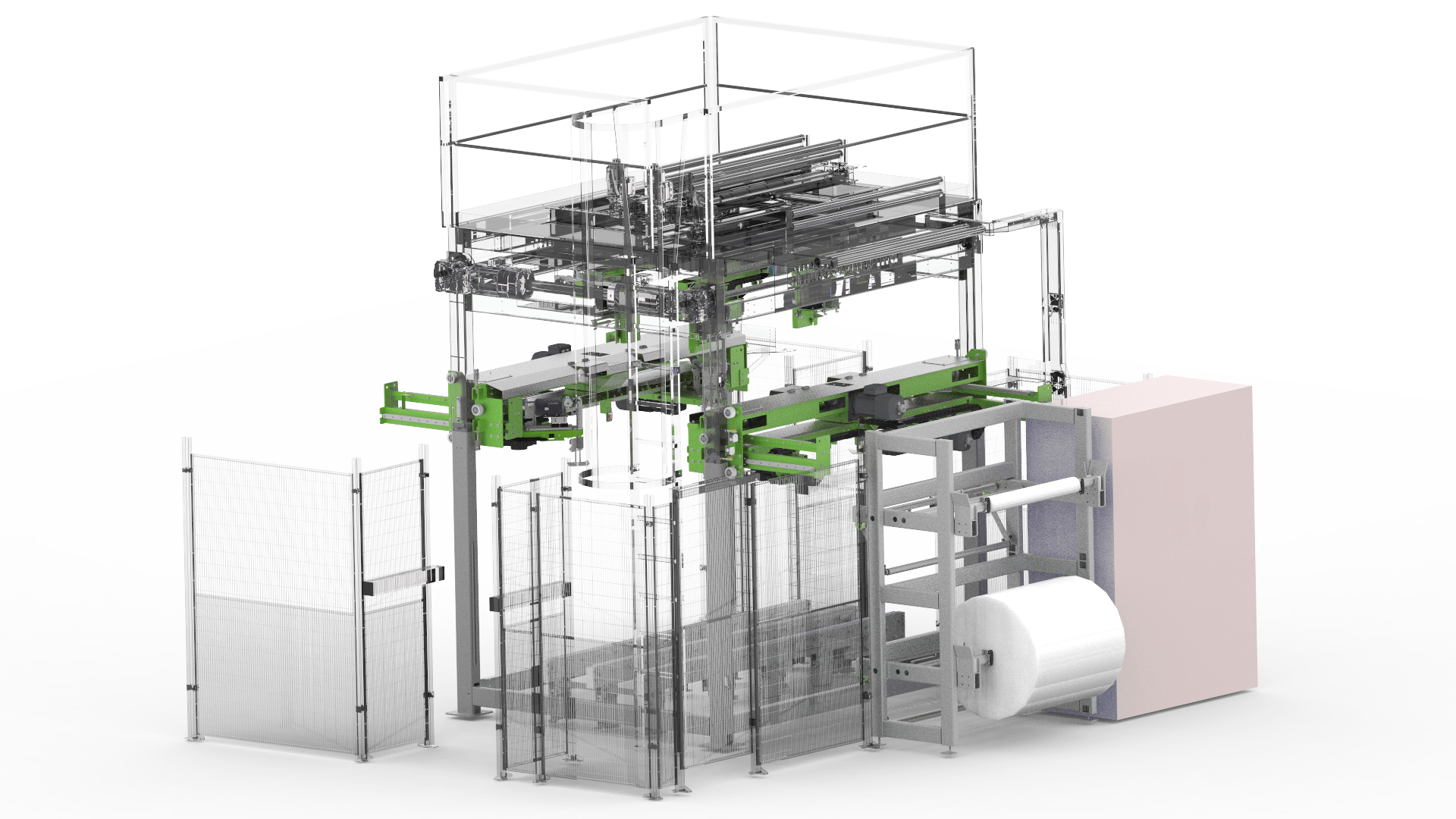

Packaging equipments contain several essential components that collaborate to guarantee reliable and reliable product packaging processes. At the core of these makers is the structure, which supplies architectural honesty and houses the different operating parts. The drive system, typically a combination of electric motors and gears, assists in the movement of elements, allowing exact operation throughout the packaging cycle.

One more vital element is the conveyor system, which moves products through various phases of the product packaging procedure. This is often complemented by sensing units and controls that keep an eye on the setting and rate of things, guaranteeing synchronization and decreasing errors. The loading system is essential for accurately dispensing the appropriate amount of product into packages, whether in liquid, powder, or strong form.

Securing systems, including warmth sealants or glue applicators, play an important function in protecting bundles, protecting against contamination and prolonging shelf life. Furthermore, classifying systems are indispensable for giving necessary item details, making sure conformity with regulations. Lastly, the control board, furnished with user-friendly user interfaces, enables operators to manage maker functions, display performance, and make changes as needed, making sure ideal productivity and performance in product packaging procedures.

Typical Upkeep Problems

Reliable procedure of packaging devices depends greatly on normal maintenance to stop usual concerns that can interfere with manufacturing. Amongst these issues, mechanical wear and tear is prevalent, particularly in components like seals, conveyors, and motors, which can cause unexpected downtimes. In addition, misalignment of components can result in ineffective procedure, triggering products to be incorrectly packaged or damaged throughout the procedure.

An additional usual upkeep issue entails the buildup of dust and debris, which can interfere with the device's sensors and relocating parts. packaging machine repair service. This not just impacts performance but can also posture security risks. Furthermore, lubrication failings can cause enhanced rubbing, causing getting too hot and ultimate element failing.

Electrical problems, typically originating from loose connections or damaged circuitry, can interrupt equipment features, causing significant manufacturing hold-ups. Software problems due to out-of-date programs or incorrect arrangements can hinder the device's operation, requiring immediate intervention. Attending to these typical upkeep issues proactively is crucial for ensuring optimum efficiency and durability of product packaging equipment.

Preventative Maintenance Techniques

Carrying out preventative maintenance strategies is essential for maintaining the effectiveness and reliability of packaging devices. These approaches encompass an organized technique to maintenance, focusing on the regular assessment and servicing of tools to preempt prospective failings. By sticking to an arranged upkeep program, drivers can recognize wear and tear on components prior to they result in significant failures.

Secret elements of a preventative maintenance method include regular inspections, cleansing, component, and lubrication substitutes based on manufacturer suggestions. Using checklists can improve this process, guaranteeing that no crucial jobs are ignored. Furthermore, keeping accurate records of maintenance tasks aids in tracking the maker's efficiency in time, promoting informed decision-making regarding future upkeep demands.

Educating staff on the importance of preventative upkeep improves compliance and cultivates a culture of aggressive care. Applying a predictive maintenance component, using data analytics and sensor technology, can even more enhance machinery efficiency by predicting failings prior to they occur.

Fixing Techniques

When encountered with malfunctions or ineffectiveness in product packaging machines, utilizing organized troubleshooting methods is crucial for determining and settling problems swiftly. The very first step in effective troubleshooting is to develop a clear understanding of the machine's functional criteria and efficiency metrics. This involves evaluating the equipment's requirements, along with any error notifies or codes presented.

Next, drivers need to perform a visual evaluation, looking for apparent signs of damages, imbalance, or wear. This frequently consists of taking a look at belts, sensors, and equipments to identify possible reasons for breakdown. Collecting operational data, such as production prices and downtime logs, can also offer insights right into repeating concerns.

Once prospective troubles are identified, utilizing a rational method to isolate the origin is vital. This might need screening individual elements or systems in a controlled way. Participating in discussions with operators that interact with the equipment on a regular basis can generate beneficial comments about unusual habits or patterns.

Fixing and Replacement Ideal Practices

A comprehensive understanding of fixing and substitute finest practices is crucial for maintaining the longevity and efficiency of product packaging equipments. On a regular basis assessing the problem of equipment components permits prompt treatment, avoiding more substantial problems that can bring about costly downtimes.

When fixings are required, it is necessary to utilize OEM (Original Devices Maker) parts to ensure compatibility and efficiency. This not only preserves the honesty of the machine but additionally promotes service warranty arrangements. Additionally, it is a good idea to keep a supply of vital spare components to help with fast substitutes and decrease operational disturbances.

For complex repair services, involving licensed technicians with specialized training in packaging equipment is suggested. They possess the know-how to identify concerns Source properly and perform fixings successfully. Recording all repair work activities and components replacements is crucial for keeping an extensive upkeep background, which can assist in future troubleshooting.

Finally, applying a proactive technique, consisting of routine inspections and predictive maintenance strategies, enhances the integrity of packaging makers. By adhering to these finest practices, organizations can make sure ideal machine performance, minimize operational dangers, and expand devices life expectancy.

Final Thought

In conclusion, a comprehensive understanding of product packaging maker components and effective upkeep techniques is crucial for optimal efficiency. By carrying out these practices, organizations can guarantee why not try this out the long life and effectiveness of packaging machines, inevitably contributing to boosted operational productivity and lowered prices (packaging machine repair service).

Reliable maintenance of product packaging machines hinges on a complete understanding of their vital parts, consisting of the frame, drive system, and sealing systems.Effective procedure of product packaging devices relies greatly on regular maintenance to protect against usual concerns that can interfere with manufacturing.Implementing preventative maintenance techniques is vital for sustaining the performance and integrity of packaging equipments. Additionally, keeping accurate documents of upkeep tasks help in tracking the maker's efficiency over time, assisting in educated decision-making pertaining to future upkeep read this post here demands.